|

LaSpaziale S1 Vivaldi I Website

|

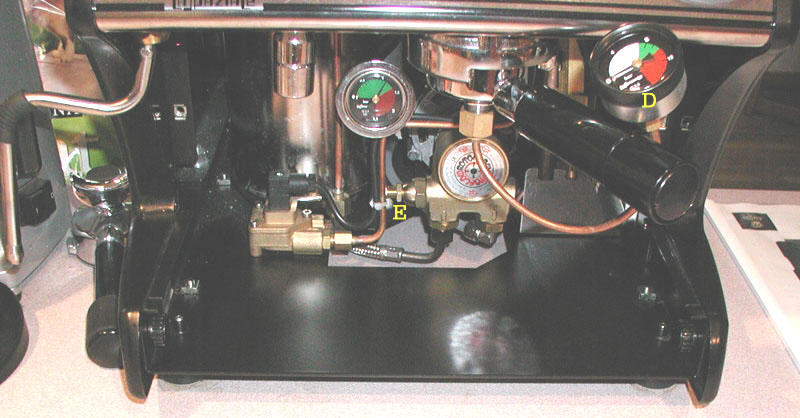

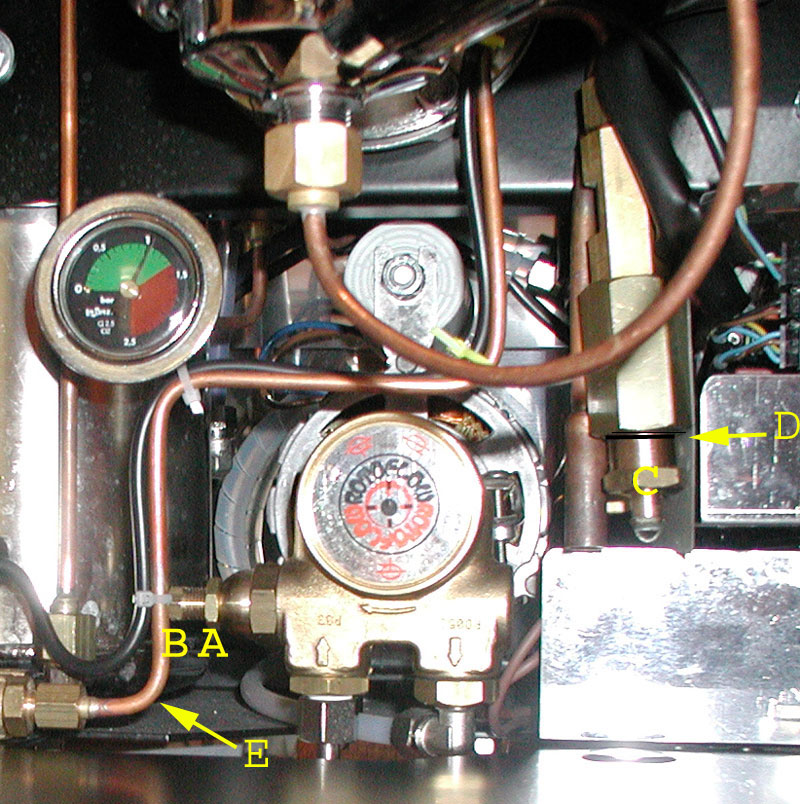

Expansion Valve R&RWhen the LaSpaziale S1 Vivaldi VI ships from the factory the Expansion valve on the group boiler should be set to open at ~12.5bar. If you have reason to doubt that it is properly set or if you're a techie that just can't leave things alone, here are the directions required to calibrate this valve.

| ||||||||