chas wrote:Then attach a power drill to the top shaft to replace the hand crank and it's almost there!

Before I bought the Pharos, I too thought the hand grinding would be the worst part. In fact, the hand grinding action is incredibly smooth and totally quiet. I actually look forward to turning the handle and have no desire to motorized it. What I don't like is all the "whacking and spanking" required to get the grounds out (they actually recommend a rubber mallet.....seriously!).

The design is great (as is the taste), but has a few fundamental flaws that must be fixed (IMO):

The first is the grinds adjustment method. It used to be simply a single nut which raised or lowered the center burr. Obviously, it needs a jam nut to hold the lower nut position. After grinder 50 or so, they realized this and made the change by adding a second nut.

The second problem is there is no reference for grind position. I see some people have started adding a grid template on top of the grinder to help. Obviously again, this should be etched into the top cover, and 2" indicator/adjustor rods should be attached to BOTH nuts

The third problem I have not heard discussed yet. They are using a coarse thread pitch for some odd reason. They should be using a finer pitch to make adjustments more precise. A simple and obvious change again.

These problems are all minor compared to the chute design problem IMO. This inner chute/hopper below the burr does not allow the grinds to fall freely. Instead, they all get stuck to the sides due to static and you must beat the grinder like an old rug to get anything out. When it does come out, it goes everywhere. You need to put a #4 coffee filter on your counter to catch 80% of the flying grinds, and you still end up sweeping. This totally unacceptable IMO.

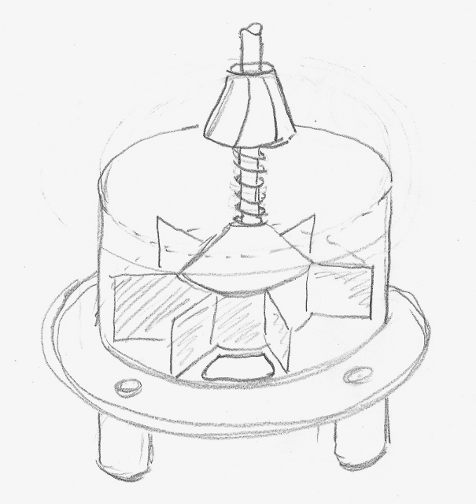

I would recommend removing the chute all together, and attaching a simple plastic vaned sweeper to the shaft inside the PVC tube (the sweeper center would also cover and protect the lower bearing from grounds, prolonging its life as well). The sweeper vane would be free to move up the shaft, but pressed down ightly with a simple loose spring around the shaft. Torque from the shaft would be transmitted to the sweeper by a square adapter on the shaft which is held in place with a screw (possibly on a local shaft flat, if required). This sweeper could easily be added to the design with only a very minor increase in manufacturing cost.

The only thing left would be to size the hole in the bottom plate to allow the grounds to drop, and slightly longer legs to fit a basket under the hole. And Voila! It would work exactly like a regular Mazzer doser, except powered by its own grinder action.

If I can find something that would simulate the sweeper vane, I'll try modding my grinder.

- Pharos Sweeper Mod

- 001 (605x640).jpg (31.32 KiB) Viewed 78529 times